Warehouse managers play a pivotal role in ensuring the smooth operation of logistics and storage facilities. However, this role comes with a myriad of challenges that can cause significant stress. At WRS UAE, we understand the unique pressures faced by warehouse managers and offer solutions to alleviate these stressors. Here are the top 9 things that stress warehouse managers and how you can address them effectively.

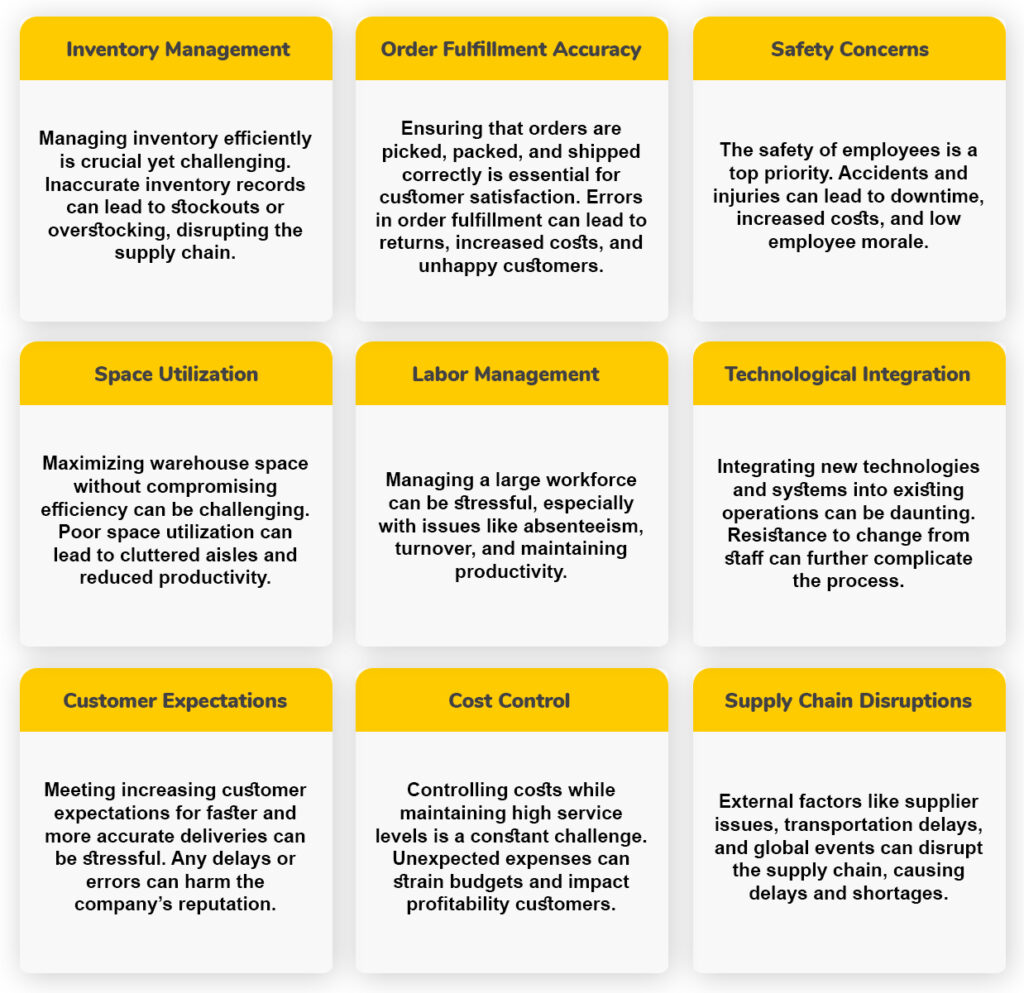

The top 9 stressors for warehouse managers

Warehouse managers face a multitude of stressors that can impact the efficiency and productivity of their operations. By addressing these challenges with strategic solutions, you can create a more streamlined, safe, and cost-effective warehouse environment.

Let’s first take a look at those stressors

In-Depth Solutions to Alleviate Warehouse Manager Stress

To dive deeper into each of these stressors and their solutions, here’s a more comprehensive guide that can help warehouse managers create a more efficient and stress-free environment.

Inventory Management

Managing inventory efficiently is a delicate balancing act. An accurate inventory ensures that the right products are available when needed, preventing stockouts and overstock situations.

Best Practices:

– **Automate Inventory Tracking:** Use RFID tags and barcode scanners to automate inventory tracking, reducing manual errors.

– **Cycle Counting:** Regularly count a subset of inventory to ensure accuracy without disrupting operations.

– **Just-In-Time (JIT) Inventory:** Implement JIT strategies to reduce holding costs and ensure that inventory is received only when needed.

Order Fulfillment Accuracy

Order fulfillment is a key area where mistakes can directly impact customer satisfaction and operational costs.

Best Practices:

– **Pick-to-Light Systems:** Use pick-to-light systems to guide warehouse staff in picking the correct items, reducing human error.

– **Order Verification:** Implement a verification process where orders are checked by multiple team members before shipping.

– **Regular Training:** Continuously train staff on best practices and update them on new processes or technologies.

Safety Concerns

A safe warehouse is a productive warehouse. Safety should be a top priority to protect employees and minimize disruptions.

Best Practices:

– **Regular Safety Audits:** Conduct regular audits to identify and address potential safety hazards.

– **Safety Training Programs:** Offer comprehensive safety training and refresher courses to all employees.

– **Protective Equipment:** Ensure all employees have access to and use necessary protective equipment.

Space Utilization

Optimizing space utilization is crucial for maintaining an organized and efficient warehouse. Effective space management can also reduce costs.

Best Practices:

– **Vertical Storage Solutions:** Utilize vertical space with multi-tier racking systems to maximize storage capacity.

– **Modular Racking Systems:** Use modular racking systems that can be adjusted or expanded as needed.

– **Dynamic Slotting:** Implement dynamic slotting to place high-velocity items in easily accessible locations.

Labor Management

Managing a warehouse workforce involves scheduling, training, and maintaining productivity. Effective labor management can significantly reduce stress and increase efficiency.

Best Practices:

– **Workforce Management Software:** Use software to manage schedules, track performance, and forecast labor needs.

– **Cross-Training:** Train employees in multiple roles to increase flexibility and coverage.

– **Incentive Programs:** Implement incentive programs to motivate employees and improve productivity.

Technological Integration

Integrating new technologies can streamline operations but may face resistance from staff.

Best Practices:

– **Phased Implementation:** Introduce new technologies in phases to allow for adjustments and minimize disruptions.

– **Employee Involvement:** Involve employees in the selection and implementation process to gain their buy-in.

– **Continuous Support:** Provide ongoing support and training to ensure staff are comfortable and proficient with new technologies.

Customer Expectations

Meeting and exceeding customer expectations is crucial for maintaining loyalty and competitiveness.

Best Practices

– **Real-Time Tracking:** Provide customers with real-time tracking of their orders to enhance transparency.

– **Efficient Returns Process:** Streamline the returns process to handle returns quickly and efficiently.

– **Customer Feedback:** Regularly collect and act on customer feedback to improve service levels.

Cost Control

Controlling costs is essential for maintaining profitability while delivering high service levels.

Best Practices

– **Cost Analysis:** Regularly analyze costs to identify areas for savings without compromising quality.

– **Energy Efficiency:** Invest in energy-efficient lighting and equipment to reduce operational costs.

– **Bulk Purchasing:** Negotiate bulk purchasing agreements with suppliers to get better rates.

Supply Chain Disruptions

Supply chain disruptions can cause significant delays and shortages, impacting overall operations.

Best Practices

– **Diversified Suppliers:** Maintain relationships with multiple suppliers to reduce dependency on a single source.

– **Predictive Analytics:** Use predictive analytics to anticipate potential disruptions and plan accordingly.

– **Buffer Stock:** Keep a buffer stock of critical items to manage short-term supply chain disruptions.

WRS UAE: Your Partner in Warehouse Efficiency

Warehouse managers face numerous challenges that can cause significant stress. However, by implementing these best practices and leveraging advanced racking solutions from WRS UAE, you can create a more efficient, safe, and cost-effective warehouse environment. Our customized racking solutions are designed to optimize your intralogistics, helping you alleviate stress and focus on driving your business forward.

At WRS UAE, we are dedicated to supporting your warehouse operations with racking solutions tailored to your specific needs.

Contact us today to learn how we can help you optimize your warehouse and reduce stress.